Editor: Sarah

In recent years, the field of personalized medicine has advanced significantly, and one of the promising innovations in this area is the integration of 3D printing technology in drug delivery systems. A study conducted by researchers at the University of Parma investigates the use of 3D-printed chitosan/alginate-based hydrogels for the controlled release of silver sulfadiazine (SSD), a commonly used antimicrobial agent for burn treatments. This research opens new possibilities for improving wound healing, particularly in the management of chronic wounds and infection control.

The Novel Approach: 3D-Printed Chitosan/Alginate Hydrogels

This study introduces a novel approach by utilizing 3D printing to design precise and customizable drug-loaded hydrogel structures. While chitosan and alginate hydrogels have been used in wound dressings, the application of 3D printing to create drug delivery systems from these materials is an emerging area of research. The team addresses a significant gap in wound care by developing a more effective and controlled method to deliver antimicrobial agents directly to wounds.

Key Findings: Modulating Drug Release

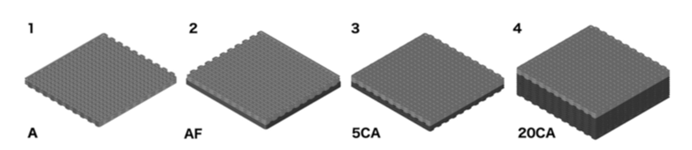

The researchers investigated four different 3D-printed hydrogel architectures and found notable variations in the release profiles of SSD. The study demonstrated that:

- Alginate-only Hydrogels: These hydrogels exhibited a rapid initial release of SSD, with 76% of the drug released within the first hour and nearly complete release after three hours.

Figure 1: Schematic representation of 3D constructs.

- Chitosan-Alginate Hydrogels: The combination of chitosan and alginate resulted in a slower and more sustained release of the drug, offering better control over the delivery and making it more suitable for long-term wound management.

Figure 2: Percent release of loaded SSD from different hydrogel combinations.

These findings highlight the potential of tailoring drug delivery systems based on the composition and architecture of hydrogels, which can be adapted to individual patient needs.

Antimicrobial Efficacy Against Common Wound Infections

The antimicrobial efficacy of these 3D-printed hydrogels was evaluated against two common bacterial strains associated with chronic wound infections: Staphylococcus aureus and Pseudomonas aeruginosa. The SSD-loaded hydrogels successfully inhibited the growth of both bacterial strains, demonstrating their potential effectiveness in combating wound infections. This antimicrobial activity is essential for promoting wound healing by preventing infection and supporting tissue regeneration.

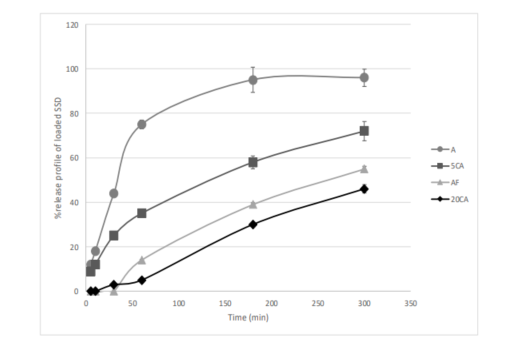

Precision and Mechanical Integrity in 3D Printing

The use of 3D printing allowed for the creation of hydrogels with high precision and mechanical integrity. The printed hydrogels not only exhibited strong antimicrobial properties but also provided a controlled and prolonged release of SSD. This is particularly important for managing chronic wounds or burn injuries that require extended periods of infection control. The combination of chitosan and alginate in these hydrogels also enhanced their mechanical properties, improving their overall stability and ease of use in clinical settings.

Figure 3: SEM pictures of 3D hydrogel.

Contributions and Key Findings: Expanded Insights

- 3D Printing of Hydrogels: The study successfully demonstrated the use of 3D printing technology to produce chitosan/alginate-based hydrogels with controlled drug release properties. The precision of 3D printing allowed the creation of customizable wound dressings with distinct architectures that could modulate the release of SSD based on the hydrogel composition.

- Controlled Drug Release: The team discovered that the release of SSD from the hydrogels could be tailored by adjusting the hydrogel architecture and polymer composition. Alginate hydrogels alone exhibited a fast release, while chitosan/alginate composites allowed for a more gradual release. These results offer new opportunities for developing personalized treatment options, where the drug release rate can be optimized based on the patient’s specific wound condition.

- Antimicrobial Testing: The SSD-loaded hydrogels showed strong antimicrobial activity, particularly against Staphylococcus aureus and Pseudomonas aeruginosa. These two bacteria are commonly found in chronic infections, especially in burn wounds, and are often resistant to many conventional antibiotics. The hydrogels demonstrated the ability to control bacterial growth, which is critical for wound healing.

- Mechanical Performance of Hydrogels: The mechanical properties of the 3D-printed hydrogels were carefully tested, with the alginate-based hydrogels exhibiting a higher degree of elasticity compared to chitosan-based hydrogels. However, when combined, chitosan enhanced the overall mechanical strength, making the composite hydrogel suitable for practical use in clinical environments. This combination also helped the hydrogels maintain their integrity while providing the flexibility required for wound care.

- Potential for Personalized Wound Care: This research lays the foundation for the development of more personalized wound care treatments. By using 3D printing, healthcare providers could customize the hydrogel scaffolds to meet the specific needs of individual patients. This could lead to better treatment outcomes and reduced healing times, particularly for patients with chronic or severe wounds.

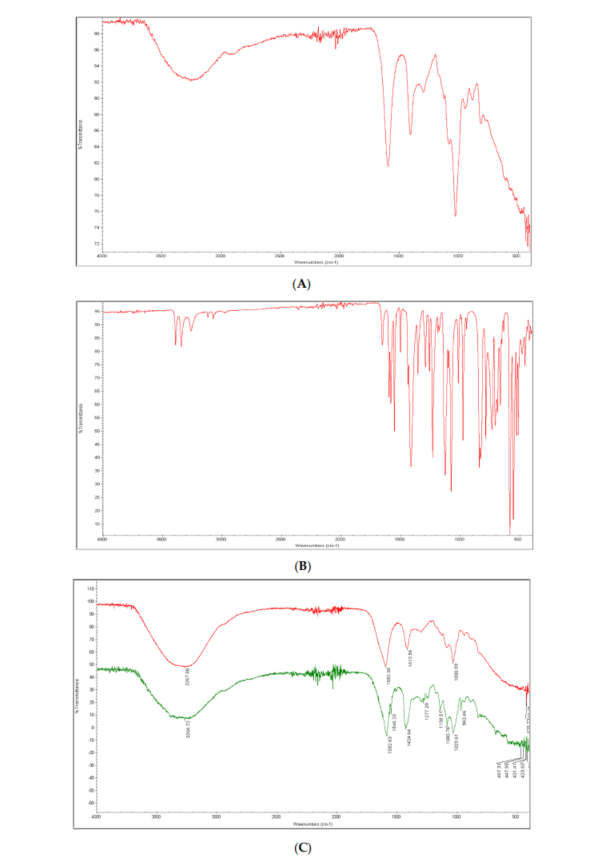

Figure 4: ATR–FTIR spectra.

Conclusion: The Future of Personalized Wound Care

This study represents a significant step forward in the field of personalized medicine, particularly in wound care. The integration of 3D printing technology with biocompatible materials such as chitosan and alginate for controlled drug delivery systems offers promising solutions for the treatment of chronic wounds and infection management. The ability to control the release of antimicrobial agents such as SSD directly at the site of infection can lead to more effective and efficient treatments, ultimately improving patient outcomes.

With further research and development, these 3D-printed hydrogels could be adapted for a wide range of applications, offering customized wound care treatments that are tailored to the individual needs of patients. The findings of this study provide a strong foundation for the future of wound healing and personalized medicine.

Reference

Bergonzi, Carlo, et al. “3D Printed Chitosan/Alginate Hydrogels for the Controlled Release of Silver Sulfadiazine in Wound Healing Applications: Design, Characterization and Antimicrobial Activity.” Micromachines, vol. 14, no. 1, 2023, p. 137. https://doi.org/10.3390/mi14010137.